Titanium Fasteners Manufacturers: The Future of Construction

In the rapidly evolving landscape of construction and manufacturing, the significance of titanium fasteners manufacturers cannot be overstated. These companies are at the forefront of providing essential components that ensure structural integrity, longevity, and performance across various applications. This article delves into the world of titanium fasteners, examining their benefits, applications, and how they revolutionize the methodologies employed by general contractors.

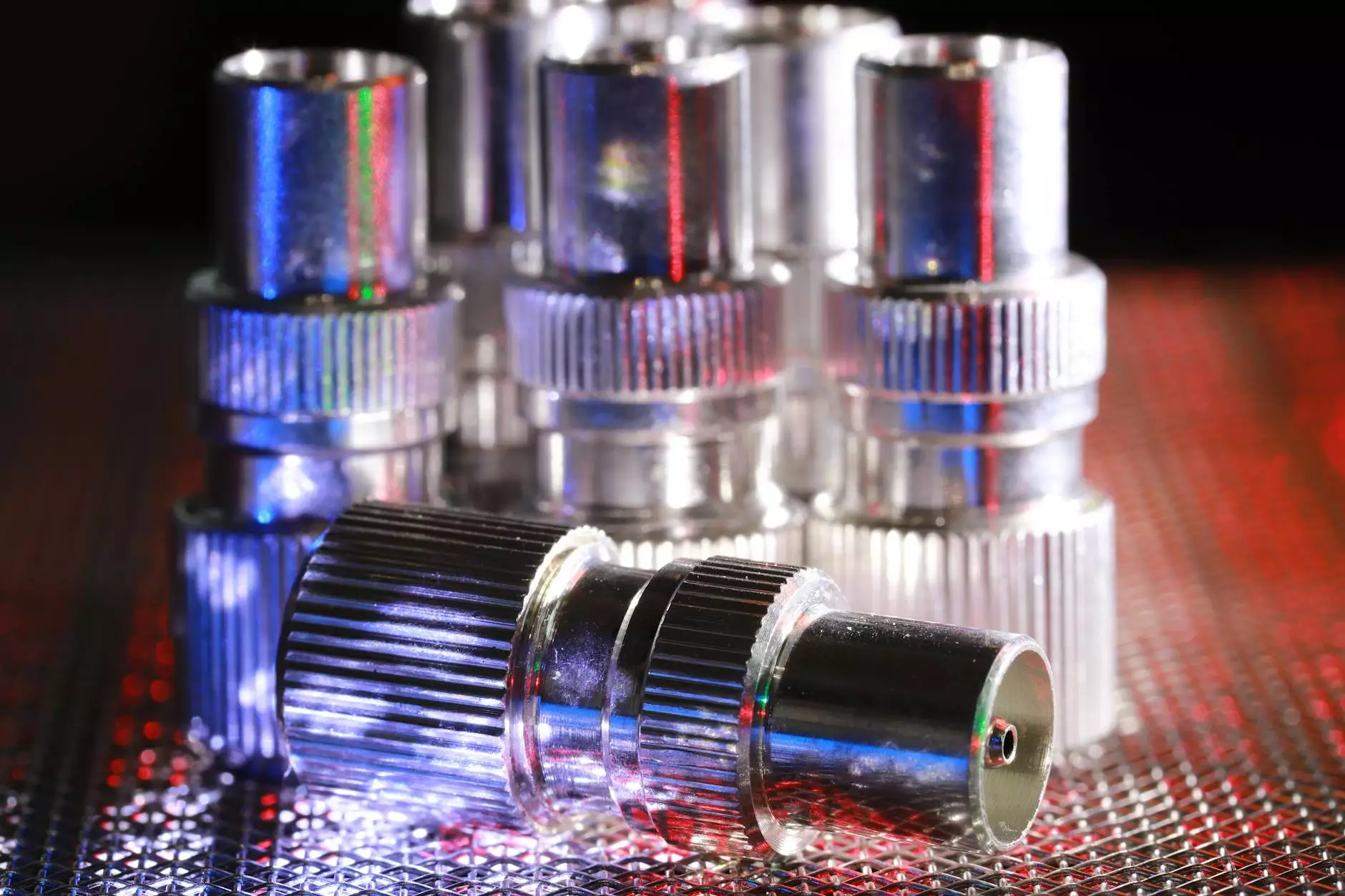

Understanding Titanium Fasteners

Titanium fasteners are components made from titanium or titanium alloys, which possess remarkable strength-to-weight ratios, exceptional corrosion resistance, and outstanding biocompatibility. This makes them ideal for numerous applications across industries, particularly in construction, aerospace, automotive, and medical sectors.

The Unique Properties of Titanium

Before diving into the specifics of titanium fasteners manufacturers, it is essential to grasp the unique properties of titanium:

- High Strength: Titanium is stronger than many steel alloys, allowing for larger spans and lighter structures.

- Corrosion Resistance: Titanium resists rust and corrosion, making it ideal for harsh environments.

- Lightweight: Weighing much less than steel, titanium fasteners contribute to overall weight reductions in a project.

- Biocompatibility: This makes titanium an excellent choice for medical applications, particularly in implants and surgical instruments.

The Role of Titanium Fasteners in Construction

Titanium fasteners are increasingly becoming a choice for general contractors seeking durability and reliability in their projects. The transition from traditional materials to titanium fasteners offers numerous advantages:

Enhanced Durability

Titanium fasteners demonstrate exceptional resistance to wear and tear. This durability translates to lower maintenance costs and longer service life, making them a wise investment for general contractors.

Weight Reduction

In construction, every pound saved counts. The lightweight nature of titanium fasteners allows for the construction of lighter structures without compromising strength. This is particularly beneficial in applications where weight is a critical factor.

Cost-Effectiveness

While the initial cost of titanium fasteners may be higher than that of traditional materials, the long-term savings due to reduced maintenance, increased lifespan, and fewer replacements often outweigh the initial expenditure. Moreover, decreased structural weight can lead to cost savings in other areas, such as the foundation and materials needed for support.

Applications of Titanium Fasteners

Various industries are harnessing the power of titanium fasteners, primarily due to their versatility. Below are some of the key sectors that utilize these components:

Aerospace Industry

The aerospace sector extensively uses titanium fasteners due to the material's favorable strength-to-weight ratio. Aircraft manufacturers rely on titanium to reduce the overall weight of the aircraft, improving fuel efficiency and performance.

Marine Applications

In marine environments, resistance to saltwater corrosion is vital. Titanium fasteners are ideally suited for marine applications, from shipbuilding to offshore structures, as they ensure longevity and reliability.

Automotive Sector

The automotive industry is adapting titanium fasteners to improve vehicle performance and decrease weight. By integrating titanium components, manufacturers enhance efficiency and sustainability.

Medical Field

Titanium fasteners are used in medical applications such as orthopedic implants and surgical instruments due to their biocompatibility. Their use ensures safety and effectiveness in patient care.

Choosing the Right Titanium Fasteners Manufacturer

With the increasing popularity of titanium fasteners, choosing the right manufacturer becomes paramount for general contractors. Here are some essential factors to consider:

Quality Standards

Ensure that your manufacturer complies with industry-specific quality standards, such as ISO certifications, to guarantee the integrity and quality of the fasteners.

Customization Capabilities

Different projects may require unique specifications. A proficient titanium fasteners manufacturer should provide customization options to meet your project's specific needs.

Technical Expertise

Look for manufacturers with a strong engineering team capable of addressing design challenges and providing support throughout the construction process.

Reputation and Experience

Research the manufacturer's reputation within the industry. Companies with a longstanding history often demonstrate reliability and customer satisfaction.

Market Trends in Titanium Fasteners

The market for titanium fasteners is witnessing significant transformations, driven by technological advancements and evolving industry demands. Here are some current trends shaping the landscape:

Innovation and Technology

The integration of advanced manufacturing techniques, such as additive manufacturing (3D printing), has revolutionized the production of titanium fasteners. This allows for more complex designs and rapid prototyping, reducing lead times substantially.

Increasing Demand for Lightweight Materials

As industries continue to prioritize efficiency and sustainability, the demand for lightweight materials like titanium is surging. General contractors are turning towards titanium fasteners to meet these demands while maintaining structural integrity.

Environmental Considerations

Sustainability is becoming a crucial factor in material sourcing. Titanium’s recyclability and durability make it a perfect fit for environmentally-conscious projects, contributing to circular economy initiatives.

Conclusion: The Future of Titanium Fasteners in Construction

The role of titanium fasteners manufacturers in the construction industry is poised to grow as innovations continue to unfold. With their unmatched properties and performance advantages, titanium fasteners present a transformative opportunity for general contractors everywhere. By opting for titanium, contractors not only enhance the quality and reliability of their projects but also align with a future that prioritizes sustainability and efficiency.

As the industry evolves, staying informed about materials, innovations, and manufacturers will ensure that general contractors remain at the pinnacle of technological advancements, leading to safer and more efficient construction practices.